|

|

You are here: Knowledge Base > Bobrick Techincal Bulletins

|

TB-87 Toilet Partition material LEED information Program Last Updated: 01/21/2008 |

||

|

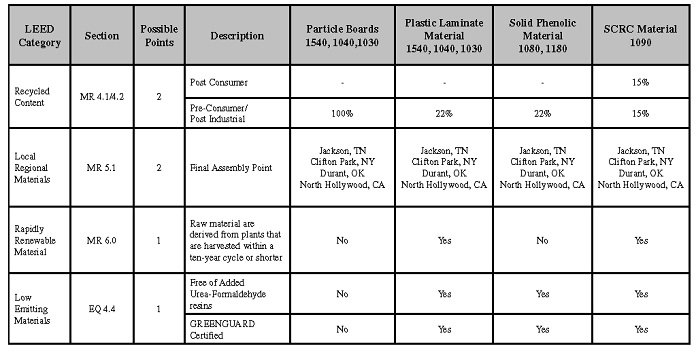

Leadership in Energy and Environmental Design (LED) Certification Program Information Version 2.2: The LEED Rating Systems are developed by the United States Green Building Council ("USGBC"). It is a voluntary standard for developing environmentally responsible, low emission and sustainable buildings. Individual products and materials used in buildings are not certified. The New Construction (NC) Version 2.2, October 2005 allows the entire construction project to be certified. The project earns "points" in each section per NC 2.2. The categories where points can be obtained from toilet partition products produced by Bobrick are as follows: Recycled Content: Awards 2 possible points for buildings that contain recycled, reused, or refurbished materials diverted from the waste stream during the manufacturing process, with points awarded as a function of the total building materials used (MR 4.1 = 10%=1 point, MR 4.2 = 20% = 1 point in addition to the MR 4.1). Credit is based on the sum of post-consumer recycled material +1/2 of post-industrial recycled material. Regional Materials: Awards two possible points for use of building materials or products that have been extracted, harvested or recovered, as well as manufactured within 500 miles of the project site for a minimum of 10% (based on cost) of the total material value. (MR 5.1 = 10% = 1 point, MR 5.2 = 20% =1 point in addition to MR 5.1). Rapidly Renewable Materials: Awards 1 point if 2.5% of the total value of all building materials used, based on cost, are derived from plants that are harvested within a ten-year cycle or less. This contributes to (MR 6.0 = 1 point) Low Emitting Materials: Awards 1 point (Credit EQ 4.4) if the composite wood and agrifiber products contain no added urea-formaldehyde resins.  see attached Bulletin

|